Description

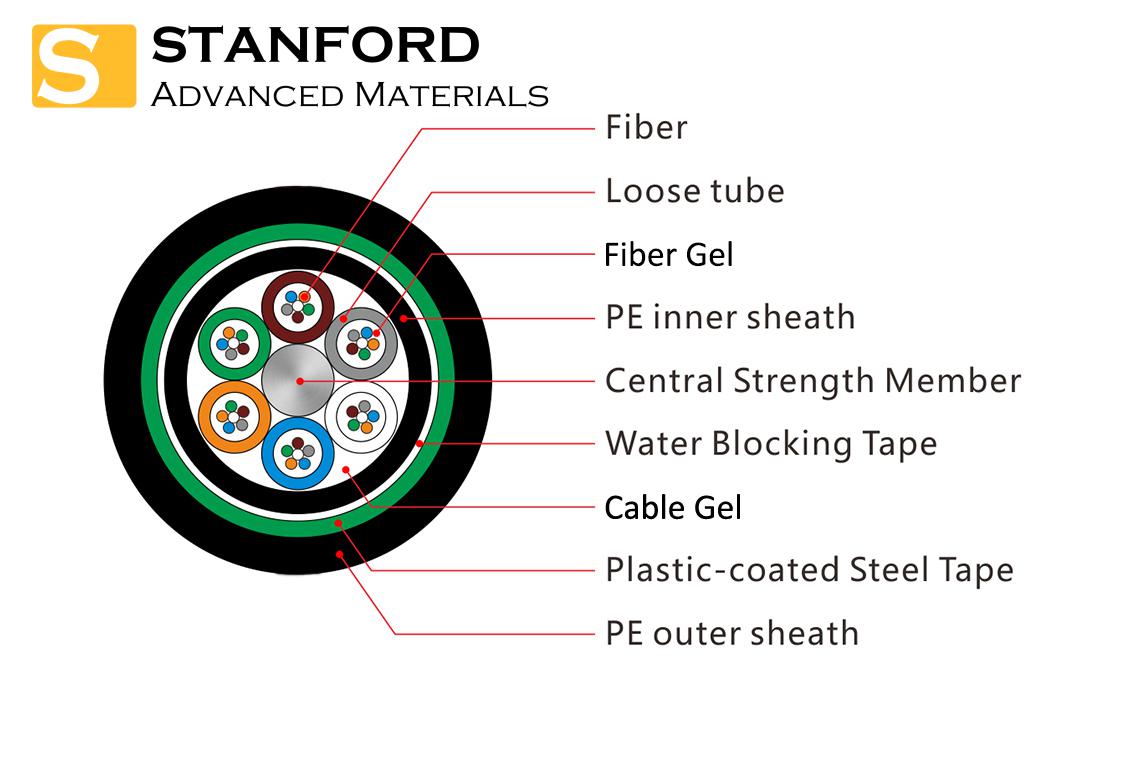

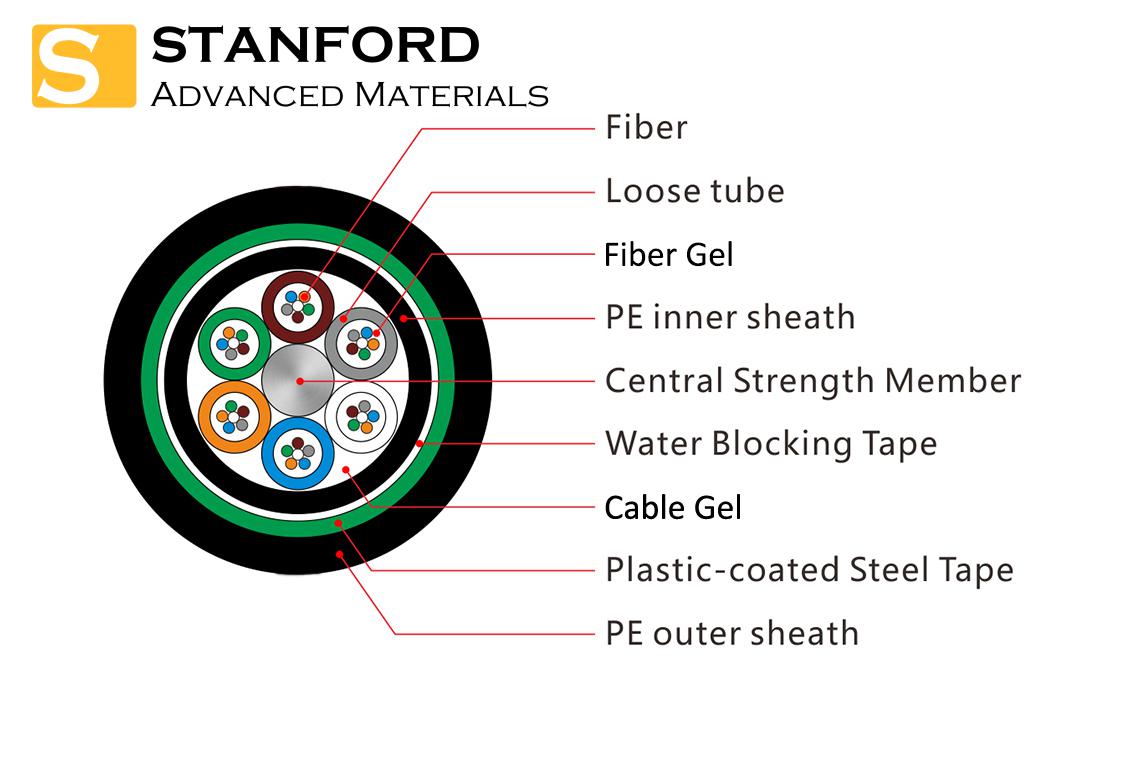

Loose Tube Layer Stranded Ordinary Armored Optical Cable features 250μm fibers housed in loose tubes made of high-modulus plastic, filled with a water-resistant compound for protection. A central steel wire, optionally sheathed in PE for high fiber counts, acts as the strength member. The tubes and fillers are stranded around the core, forming a compact, circular structure.

The core is filled with a water-blocking compound, covered with a thin PE inner sheath, and reinforced with corrugated steel tape (PSP) for durability. A robust PE outer sheath completes the design, ensuring excellent mechanical strength and water resistance, ideal for outdoor use.

Feature

Cross-section Diagram

- Excellent Mechanical and Temperature Performance

- High-Strength Loose Tube with Hydrolysis Resistance

- Specialized Tube Filling Compound

- Superior Crush Resistance and Flexibility

- Comprehensive Water-Tightness Design

- Multiple measures are implemented to ensure water-blocking capabilities:

-

- Steel Wire Central Strength Member: Provides mechanical support and helps prevent water ingress.

- Loose Tube Filling Compound: Protects fibers and blocks moisture inside the tube.

- 100% Cable Core Filling: Ensures complete moisture resistance throughout the cable core.

- PSP (Polyethylene Steel Tape) Moisture Barrier: Enhances the cable’s resistance to water penetration.

- Water-Blocking Material: Adds an additional layer of water resistance for long-term reliability.

Application Scenario

GYTY53 Optical Cable is particularly suitable for outdoor application scenarios that require high mechanical strength, moisture resistance, and waterproofing, such as long-distance communication lines, urban backbone networks, rural communications, and other optical fiber wiring needs in complex environments.

Designed for direct underground installation, its double steel tape armor provides excellent protection against mechanical impacts and external pressure, eliminating the need for additional conduits.

Suitable for deployment in ducts, offering high tensile strength and ease of installation, with enhanced protection against environmental factors.

- High-Humidity or Wet Environments

The water-blocking gel and robust water-resistant design make it ideal for use in areas with high groundwater levels or humid conditions.

- Rural and Long-Distance Communication

Used in rural networks, long-distance inter-city, and inter-provincial communication lines due to its durability and resistance to environmental stress.

Commonly deployed in metropolitan and backbone networks for stable and reliable data transmission over long distances.

- Harsh Outdoor Environments

Suitable for challenging outdoor settings, including areas prone to rodent damage, mechanical stress, or temperature fluctuations.

Can be used for aerial applications with proper supports, ensuring excellent performance under varying weather conditions.

Optical Characteristics

|

Fiber Type

|

G.652

|

G.655

|

50/125μm

|

62.5/125μm

|

|

Attenuation

(±20℃)

|

@850nm

|

-

|

-

|

≤3.0 dB/km

|

≤3.3 dB/km

|

|

@1300nm

|

-

|

-

|

≤1.0 dB/km

|

≤1.0 dB/km

|

|

@1310nm

|

≤0.36 dB/km

|

≤0.40 dB/km

|

-

|

-

|

|

@1550nm

|

≤0.22 dB/km

|

≤0.23dB/km

|

-

|

-

|

|

Bandwidth

(Class A)

|

@850nm

|

-

|

-

|

≥500 MHz·km

|

≥200 MHz·km

|

|

@1300nm

|

-

|

-

|

≥1000 MHz·km

|

≥500 MHz·km

|

|

Numerical Aperture

|

-

|

-

|

0.200±0.015NA

|

0.275±0.015NS

|

|

Cable Cut-off Wavelength λcc

|

≤1260nm

|

≤1450nm

|

-

|

-

|

Technical Parameters

|

Cable Type

|

Fiber Count

|

Loose Tubes

|

Filling Ropes

|

Reference Cable Weight

kg/km

|

Tensile Strength

Long/Short-Term

N

|

Crush Resistance

Long/Short Term

N/100mm

|

Bending Radius

Static/Dynamic

mm

|

|

GYTY53-2~6Xn

|

2~6

|

1

|

4

|

160

|

1000/3000

|

1000/3000

|

12.5/25D

|

|

GYTY53-8~12Xn

|

8~12

|

2

|

3

|

160

|

|

GYTY53-14~18Xn

|

14~18

|

3

|

2

|

160

|

|

GYTY53-20~24Xn

|

20~24

|

4

|

1

|

160

|

|

GYTY53-26~30Xn

|

26~30

|

5

|

0

|

160

|

|

GYTY53-32~36Xn

|

32~36

|

6

|

0

|

160

|

|

GYTY53-38~48Xn

|

38~48

|

4

|

1

|

174

|

|

GYTY53-50~60Xn

|

50~60

|

5

|

0

|

174

|

|

GYTY53-62~72Xn

|

62~72

|

6

|

0

|

185

|

|

GYTY53-74~84Xn

|

74~84

|

7

|

1

|

214

|

|

GYTY53-86~96Xn

|

86~96

|

8

|

0

|

214

|

|

GYTY53-98~108Xn

|

98~108

|

9

|

1

|

245

|

|

GYTY53-110~120Xn

|

110~120

|

10

|

0

|

245

|

|

GYTY53-122~132Xn

|

122~132

|

11

|

1

|

281

|

|

GYTY53-134~144Xn

|

134~144

|

12

|

0

|

281

|

|

GYTY53146~216Xn

|

146~216

|

13-18

|

5-0

|

281

|

*Sizes and performance values can be specified by customers.

Get a Quote

Get a Quote