Fiber Optic Connector Selection: Your Ultimate Type Guide

1. Introduction

With the rapid advancement of information technology, the demand for high-bandwidth and long-distance communication has surged, outpacing the capabilities of traditional copper cabling. Fiber optic communication has emerged as the backbone of modern communication networks due to its exceptional transmission performance. Fiber optics offer higher bandwidth, lower signal loss, and immunity to electromagnetic interference, making them essential in data centers, metropolitan area networks (MANs), and long-haul telecommunications.

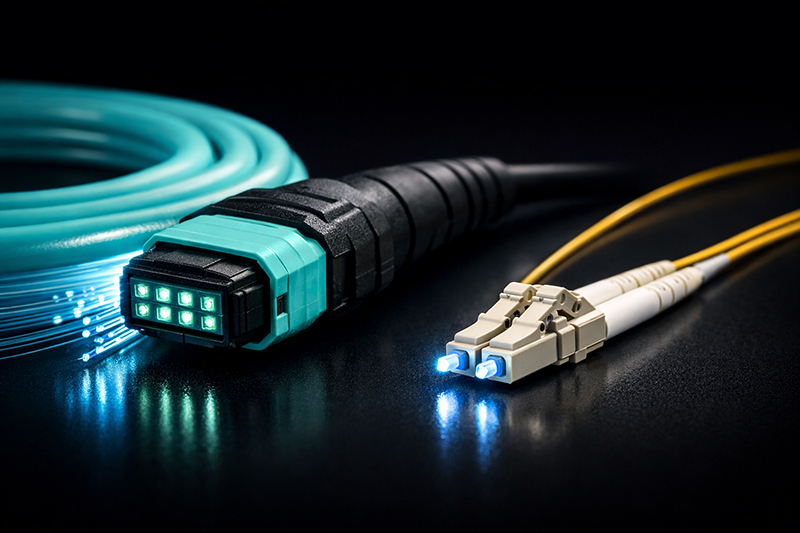

Within the fiber optic communication system, fiber optic connectors play a crucial role. They are responsible for precisely aligning the ends of optical fibers to ensure efficient signal transmission. The quality of these connectors directly impacts the performance and reliability of the entire network, making the selection of appropriate fiber optic connectors vital.

This article aims to provide a comprehensive overview of fiber optic connectors, covering fundamental knowledge, common types and their applications, classification standards, selection guidelines, and installation and maintenance practices. By delving into these aspects, readers will gain a thorough understanding of the role fiber optic connectors play in communication networks and receive practical guidance for their selection and upkeep.

2. Basics of Fiber Optic Connectors

What are Fiber Optic Connectors

Fiber optic connectors are devices designed to facilitate the quick connection and disconnection of optical fibers. Their primary function is to accurately align the fiber ends, enabling lossless transmission of optical signals. These connectors are widely used in various fiber optic communication equipment, including switches, routers, and optical modules.

Basic Components of Fiber Optic Connectors

-

Plug and Socket: The plug is attached to the end of the fiber, while the socket is fixed to the device or patch panel. These components mechanically engage to establish the optical connection.

-

Alignment Pins and Spring Mechanism: Alignment pins ensure precise alignment between the plug and socket, while the spring mechanism provides the necessary elasticity to maintain a stable and reliable connection.

-

Sealing and Protection Structures: To protect the fiber end faces from environmental contamination and physical damage, connectors are typically equipped with sealing rings or protective caps, enhancing their suitability for various environments.

3. Common Types of Fiber Optic Connectors

LC Connector

The LC (Lucent Connector) is known for its compact design, allowing for high-density connections. It is smaller than the standard SC connector, making it ideal for environments where space is at a premium.

LC connectors are commonly used in data centers, high-speed network equipment, and fiber optic switches due to their ability to support dense configurations.

SC Connector

The SC (Subscriber Connector) features a square-shaped design and is easy to plug and unplug. Its snap-in mechanism makes it suitable for applications requiring frequent connections and disconnections.

SC connectors are widely used in telecommunications equipment, instrumentation, and network termination points.

FC Connector

The FC (Ferrule Connector) utilizes a threaded mechanism for secure attachment, making it highly stable and resistant to vibrations. This makes it suitable for environments subject to movement or mechanical stress.

FC connectors are often found in broadcast equipment, industrial control systems, and testing instruments where a robust connection is essential.

MTP/MPO Connector

MTP (Mechanical Transfer Push-on) and MPO (Multi-fiber Push-On) connectors support multiple fibers in a single rectangular interface, enabling high-density connections essential for large-scale fiber installations.

These connectors are predominantly used in data centers, high-performance computing facilities, and fiber optic distributed sensing systems where high fiber counts and density are required.

Other Types

-

ST Connector: The ST (Straight Tip) connector has a cylindrical design and is commonly used for multimode fiber systems. It is known for its durability and ease of use.

-

MU Connector: The MU (Miniature Unit) connector is a smaller variant ideal for connecting equipment within tight spaces, such as in instrumentation devices.

-

DIN Connector: The DIN connector is prevalent in industrial applications, offering excellent resistance to electromagnetic interference and mechanical robustness.

4. Classification Standards of Fiber Optic Connectors

Classification by Number of Fibers

-

Single-Fiber Connectors: Designed for connecting a single optical fiber, these connectors are suitable for simplex applications where only one fiber is needed.

-

Multi-Fiber Connectors: Capable of connecting multiple fibers simultaneously, these connectors are ideal for high-density and multiplexed applications, reducing the number of individual connections required.

Classification by Applicable Environment

-

Indoor Connectors: These connectors are designed for use within controlled environments, featuring simple designs that focus on ease of use and reliable performance in stable conditions. Also see our indoor optical cable.

-

Outdoor Connectors: Engineered to withstand harsh environmental conditions, outdoor connectors incorporate waterproofing, dust resistance, and durability to ensure reliable performance in outdoor installations. Also see our outdoor optical cable.

Classification by Installation Method

-

Panel-Style Connectors: Installed on panels or patch panels, these connectors facilitate organized management and easy access for maintenance and modifications.

-

Modular Connectors: Offering flexible installation options, modular connectors can be combined and configured to meet specific application requirements, making them adaptable to various deployment scenarios.

5. Fiber Optic Connector Selection Guide

Considerations

-

Bandwidth Requirements: Different connectors support varying bandwidth capacities. It is essential to choose connectors that can handle the required data rates to ensure optimal performance.

-

Transmission Distance: For long-distance transmissions, connectors with low insertion loss and minimal signal attenuation are crucial to maintain signal integrity over extended distances.

-

Environmental Conditions: Factors such as temperature fluctuations, humidity, and vibration can impact connector performance. Selecting connectors with appropriate protective features ensures reliability in the intended environment.

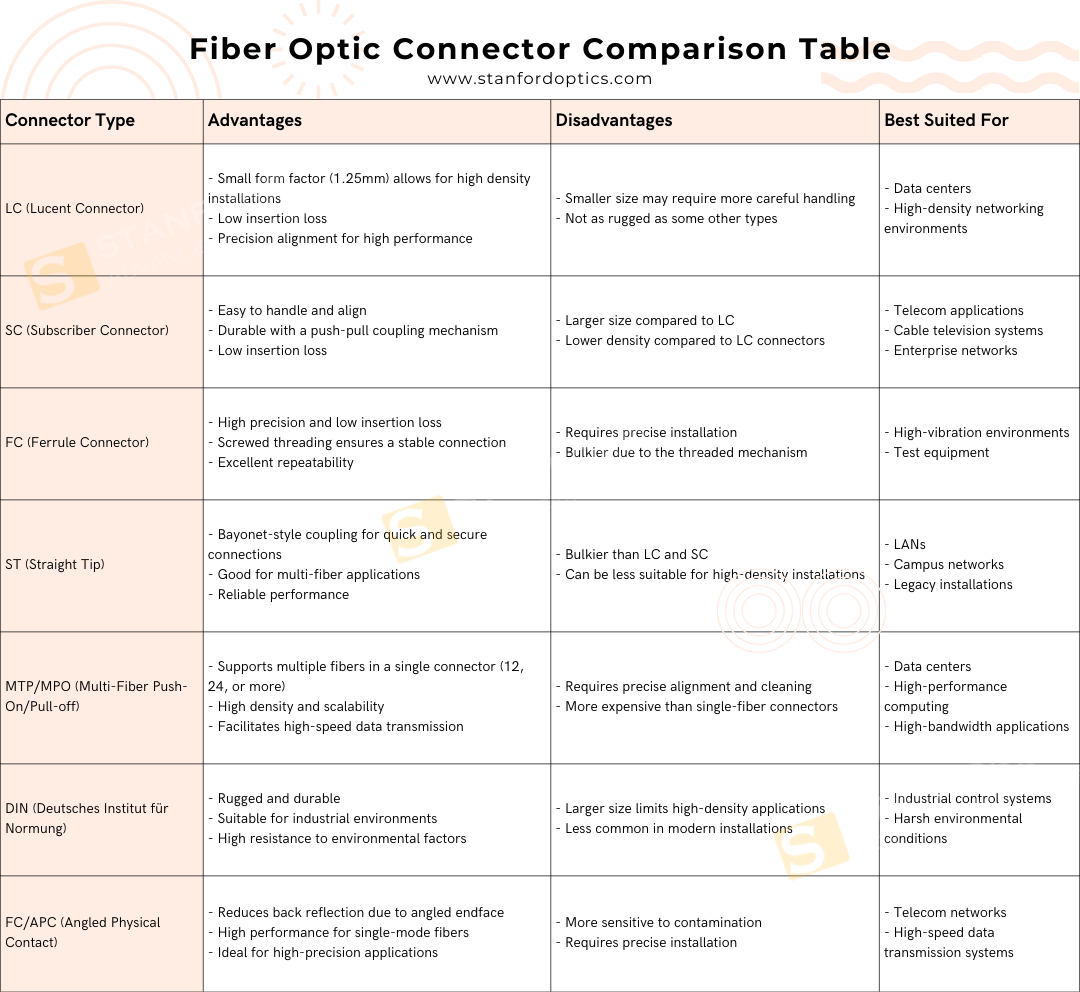

Pros and Cons of Different Connector Types

-

Compact and High-Density Designs: Connectors like the LC offer space-saving benefits, making them suitable for dense installations. However, their smaller size may require more precise handling during installation.

-

Insertion Cycles and Durability: SC connectors are durable and support frequent plug-and-unplug cycles, making them ideal for environments where connections are regularly reconfigured. Conversely, FC connectors provide greater stability in high-vibration settings but may be less convenient for frequent adjustments.

Application Matching

-

Data Centers: Require high-density and multi-fiber connectors such as MTP/MPO to support extensive fiber optic cabling and high bandwidth demands.

-

Telecom Base Stations: Demand durable connectors like FC and DIN types that can withstand outdoor conditions and mechanical stresses.

-

Industrial Control: Need connectors with strong anti-interference and protective features, making DIN and ST connectors suitable choices.

6. Installation and Maintenance of Fiber Optic Connectors

Installation Steps

-

Preparation Work:

- Cleaning: Ensure that the fiber end faces are free from dust, dirt, and oils using specialized cleaning tools and materials.

- Inspection: Examine connector components for any damage or defects before use to prevent potential signal loss or connection issues.

-

Connection and Fixation:

- Insert the fiber into the connector, ensuring that alignment pins are correctly engaged.

- Secure the connector by tightening or locking it in place to establish a stable and reliable optical connection.

Maintenance Precautions

-

Regularly Check Connection Status: Periodically inspect connectors to ensure they remain securely attached and free from signs of wear or damage. Promptly tighten or replace connectors as needed.

-

Cleaning and Dustproof Measures: Maintain the cleanliness of connector end faces by using appropriate cleaning tools and protective covers to shield against contaminants that can degrade transmission quality.

Common Problems and Solutions

-

Excessive Optical Loss:

- Cause: Potential sources include contamination of the fiber end faces, misalignment of connectors, or physical damage to the fiber.

- Solution: Clean the connector end faces meticulously, reconnect the fibers ensuring proper alignment, and inspect the fibers for any signs of damage, replacing them if necessary.

-

Unstable Connections:

- Cause: Loose or improperly secured connectors can lead to unstable connections.

- Solution: Reattach the connectors, ensuring that alignment pins are properly seated and the connectors are securely locked in place.

7. Summary

Fiber optic connectors are essential components in modern communication systems, ensuring the integrity and efficiency of optical signal transmission. Their performance directly impacts network bandwidth, stability, and transmission distances, making the appropriate selection crucial for maintaining high-quality communication. Choosing the right connector type tailored to specific applications and environments not only enhances system performance but also minimizes maintenance costs and operational disruptions.

Stanford Optics focuses on advancing connector technology by providing solutions that meet the evolving demands of fiber optic networks.