Description

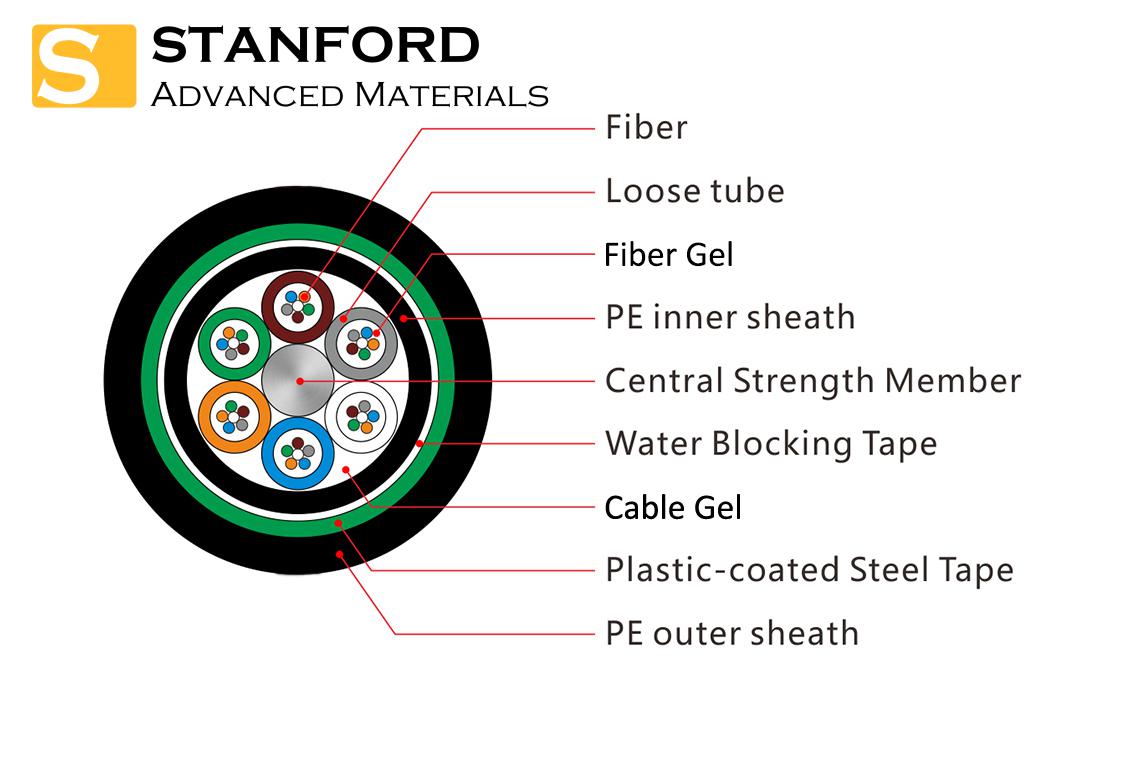

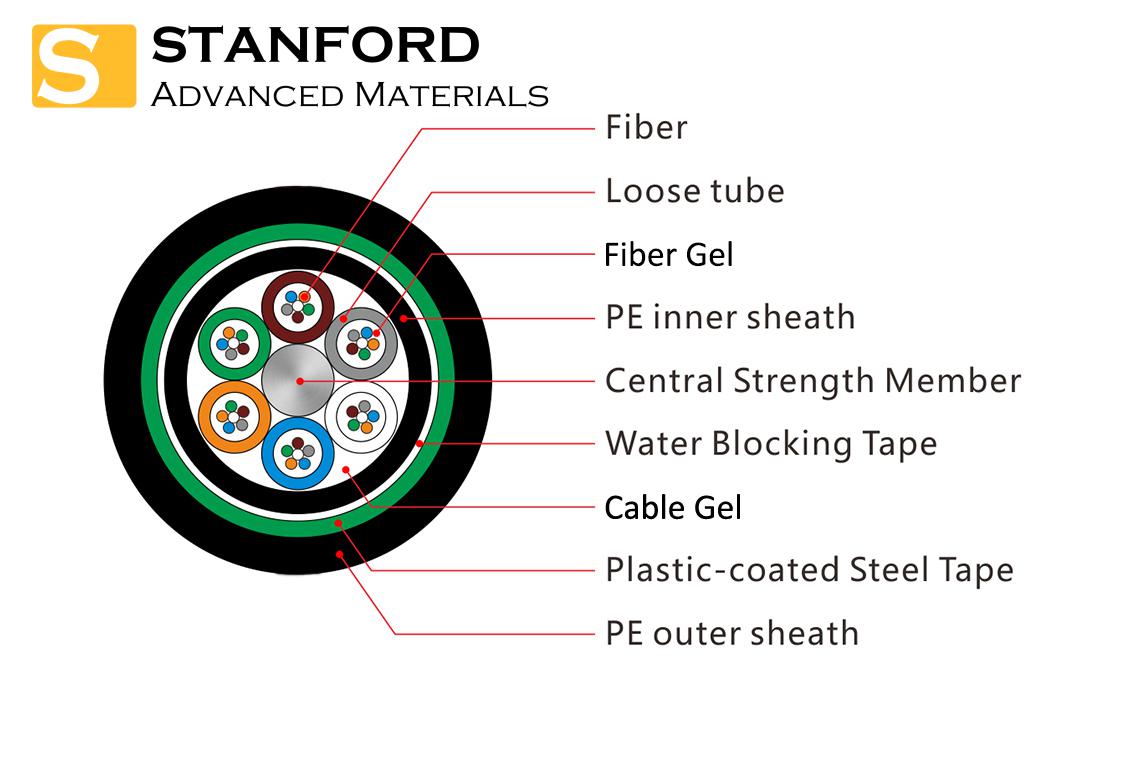

This cable is made up of loose tubes of high-strength plastic with each one filled with a water-blocking compound to protect the fibers. The strength member of steel wire is positioned at the center of the cable, sometimes with polyethylene (PE) coating if extra fiber numbers are required. Loose tubes and fillers are stranded over this central member to form a dense and round core.

The center is then covered with an Aluminum Polyethylene Laminate (APL) layer, fully filled with compound to exclude water. The center is topped with a thin PE inner sheath, followed by a corrugated steel tape layer (PSP). The structure is finally topped with a hard PE outer sheath, giving the cable mechanical strength and waterproofing.

Feature

Cross-section Diagram

- Robust mechanical performance over a wide temperature range.

- Highly resistant loose tubes to hydrolysis with high structural strength.

- Special filling compound inside tubes for protection of fibers.

- Outdoor long life with PE outer sheath resistant to UV.

- Good crush resistance and stable structure.

- Multi-layer water blocking design:

- Inner steel wire strength member ensures stability.

- Protection from moisture by tube filling compound.

- Entirely filled core prevents water intrusion through openings.

- Double APL layers create a durable water barrier.

Application Scenario

- Direct Burial: Single steel wire armor allows direct underground installation in stable or low-stress locations without extra protection.

- Duct Installation: Flexible and lightweight, designed to be pulled over long distances in conduits.

- Moisture-Prone Regions: Fully gel-filled design offers high longitudinal strength against water, used near rivers, lakes, or zones of high ground water.

- Urban and Rural Backbones: Used for transmission of signals over long distances in city and rural backbones despite environmental stress.

- Low-Stress Environments: Performs well under steady geology with negligible external forces.

- Outdoor Communication Networks: Rodent-proof armored design, suitable for forest or mountain regions.

- Aerial Installations: Installable above with proper support, maintaining operation in wind, rain, and other ambient conditions.

Optical Characteristics

|

Fiber Type

|

G.652

|

G.655

|

50/125μm

|

62.5/125μm

|

|

Attenuation

(±20℃)

|

@850nm

|

-

|

-

|

≤3.0 dB/km

|

≤3.3 dB/km

|

|

@1300nm

|

-

|

-

|

≤1.0 dB/km

|

≤1.0 dB/km

|

|

@1310nm

|

≤0.36 dB/km

|

≤0.40 dB/km

|

-

|

-

|

|

@1550nm

|

≤0.22 dB/km

|

≤0.23dB/km

|

-

|

-

|

|

Bandwidth

(Class A)

|

@850nm

|

-

|

-

|

≥500 MHz·km

|

≥200 MHz·km

|

|

@1300nm

|

-

|

-

|

≥1000 MHz·km

|

≥500 MHz·km

|

|

Numerical Aperture

|

-

|

-

|

0.200±0.015NA

|

0.275±0.015NS

|

|

Cable Cut-off Wavelength λcc

|

≤1260nm

|

≤1450nm

|

-

|

-

|

Technical Parameters

|

Cable Type

|

Fiber Count

|

Loose Tubes

|

Filling Ropes

|

Reference Cable Weight

kg/km

|

Tensile Strength

Long/Short-Term

N

|

Crush Resistance

Long/Short Term

N/100mm

|

Bending Radius

Static/Dynamic

mm

|

|

GYTA53-2~6Xn

|

2~6

|

1

|

5

|

177

|

600/1500

|

300/1000

|

10D/20D

|

|

GYTA53-8~12Xn

|

8~12

|

2

|

4

|

177

|

|

GYTA53-14~18Xn

|

14~18

|

3

|

3

|

177

|

|

GYTA53-20~24Xn

|

20~24

|

4

|

2

|

177

|

|

GYTA53-26~30Xn

|

26~30

|

5

|

1

|

177

|

|

GYTA53-32~36Xn

|

32~36

|

6

|

0

|

177

|

|

GYTA53-38~48Xn

|

38~48

|

4

|

1

|

194

|

|

GYTA53-50~60Xn

|

50~60

|

5

|

0

|

194

|

|

GYTA53-62~72Xn

|

62~72

|

6

|

0

|

204

|

|

GYTA53-74~84Xn

|

74~84

|

7

|

1

|

239

|

|

GYTA53-86~96Xn

|

86~96

|

8

|

0

|

239

|

|

GYTA53-98~108Xn

|

98~108

|

9

|

1

|

275

|

|

GYTA53-110~120Xn

|

110~120

|

10

|

0

|

275

|

|

GYTA53-122~132Xn

|

122~132

|

11

|

1

|

312

|

|

GYTA53-134~144Xn

|

134~144

|

12

|

0

|

312

|

|

GYTA53146~216Xn

|

146~216

|

13-18

|

5-0

|

312

|

*Sizes and performance values can be specified by customers.

Get a Quote

Get a Quote